These days, many people are interested in answer to the question: Chevy truck rear end interchange? This may also occur, as a Chevy truck can be useful in a wide variety of situations and tasks.

In general, this is a truck mechanics topic that only professionals can know about. So, below we have analyzed the most important details to be able to make an excellent trade-in.

In turn, this is helpful when a truck is needed for heavy-duty work. In this case, you can get a bad result when the rear end of a Chevy truck has not been designed for heavy-duty work.

Either way, with the proper information, a user will have the ability to get the parts needed for this type of heavy-duty work.

Additionally, knowing the rear end of a Chevy truck allows one to know the true capabilities that each of these vehicles can offer. Even if the time comes to apply maintenance or repairs, this guide can also help it.

Let’s analyze what constitutes the rear end of a Chevy truck.

Chevy Truck Rear-end Gears

First of all, it is necessary to mention that the gears are necessary and are included in the differentials and axles. So, the rear gears are located in the rear differential and rear axle of the vehicle.

In turn, the gears are the essential components that allow the rear wheels to receive power from the vehicle’s engine. Thus, the gears have a certain size and function to cope with the power of the engine.

In this manner, the energy is passed on to the driveline and, of course, to the vehicle’s wheels. In this way, the vehicle’s wheels can receive the power from the engine to start turning, which allows the vehicle to gain speed.

Both the transmission and the engine’s operation are designed so that the drive shaft begins to rotate. In turn, inside an axle, the drive shaft is coupled together with a pinion.

Of course, this pinion must be very robust to be able to cope with the power and the transfer of this power to the rear axle of the vehicle.

In turn, the pinion gear works in combination with a larger gear to start the whole system turning. In general, the larger gear can also be called a ring gear.

Smaller gears can also be found in the differential case whose component is attached to the ring gear. In particular, the latter components are suitable for the vehicle to drive through curves.

Also, the vehicle does not produce vibrations due to the specific design of all these parts. After all, this set of components and gears of different sizes allows the wheels to receive the power from the engine.

However, the gears are only one part of the whole system and have a certain size to function.

What is Chevy Rear end Differential

First of all, it is necessary to consider that the rear differential is usually included in a wide variety of vehicles besides Chevy trucks. So, you can easily find a rear differential in an SUV, car, or different trucks.

It is one of the essential parts to complete the automotive mechanical system of a wide variety of vehicles. Thus, we can see that the rear differential is hooked up to the transfer case or the transmission.

This connection is usually established thanks to the driveshaft. As we have mentioned, it is one of the important components for a vehicle to operate.

In this sense, a vehicle’s rear wheels can receive power from the engine thanks to this component. Simultaneously, it is not a longitudinal design or a component that is along with the vehicle.

Therefore, changing the direction of the power is that the rear differential needs to be implemented in a car. In this way, the differential can deliver motor torque to the rear tires.

For this purpose, a specific design is incorporated in these components. To be able to change the 90° direction, some gears are required in the differential. This is significant since it is necessary to deal with a 90° design in the zone of the rear axles.

Besides, the rear differential also often incorporates half shafts to complete the functionality. So, these components allow the wheels to be connected and have the ability to turn.

In particular, the rear differential is one of the components that allows the engine power to reach the wheels and the vehicle to achieve speed. Even when the rear differential needs maintenance or repairs, many vehicles cannot be used.

Chevy Rear end Gear Ratios

All vehicles have a particular gear ratio at the rear. Of course, this gear ratio can be modified as long as the right size components are available.

To modify this gear ratio, a rear casing and the dimensions of this component are required. The rear housing has a specific size, which also works with a precise pinion and ring gear.

The RPO code is usually included in the trunk in the glove box on many General Motors vehicles.

Also, there are 164 different codes, so it is necessary to know each vehicle’s code. Thus, this code allows you to know the specific type of rear-end that each vehicle has.

To do this, a series of steps can be followed to determine the specifications of the Chevy truck’s rear end. In principle, the label is usually included in some bolt of the differential cover.

Here it is possible to know the factory gear ratio. Along with that, to know the exact gear ratio, the differential cover must be removed. This even lets you know if a limited-slip or open differential.

Then the teeth of the small gear must be counted on the pinion. In other words, you should check the large gear, and the number of teeth included when you find this component attached to the differential.

It is also necessary to divide the teeth number of the ring gear with the pinion’s number of teeth. Specifically, this is the gear ratio.

Therefore, knowing the gear ratio allows you to replace parts or change the gear ratio more efficiently. For either of these purposes, knowing the gear ratio is very useful.

Chevy Truck Rear end Interchange: Upgrade Gears

Chevy Truck 10 Bolt Rear end Identification

General Motors has included the 10-bolt differential in a wide variety of vehicles over a few decades. In this case, some of these rear differentials feature limited slip technology.

In turn, final drive gear ratios can vary depending on the many uses of this 10-bolt differential. To apply a rear-drive axle maintenance or repair needed, it is helpful to identify these components.

That is why some simple steps can be followed in identifying the 10-bolt rear differential.

Prepare the Vehicle

Preparing the vehicle simply consists of parking the Chevy truck rear end interchange in an appropriate place to work. At the same time, here, it is important not to forget the parking brake to prevent the vehicle from moving unintentionally.

Even remember that you will need to work and be located right under the truck. So, using the handbrake is a basic safety aspect.

Examine the Rear Axle

Here it is necessary to continue examining the rear axle carrier. Of course, this particular component is located just under the truck. In this case, an around cover can be found to detect the rear axle carrier.

Generally, this is usually incorporated between the right and left axle tubes. Undoubtedly, all that can be easily seen when the person works from the rear of the vehicle.

Those people who are beginners in truck mechanics will have to take their time to be able to recognize each of these parts.

Identifying the Rear Differential

At this point, the differential stage should be secured with a certain number of bolts. So, when the differential cover to the carrier is secured with ten bolts, you will have found the identification.

The 10-bolt differential uses ten bolts to secure these components. In turn, a two or three-digit identification number can be incorporated.

Particularly, it is located on the differential cover, on the bottom right-hand corner of the differential cover. In turn, this code is included when postreaction is incorporated into the differentials.

Chevy Truck 12 Bolt Rear end Identification

As with the identification of the 10-bolt rear differential, a similar procedure must be performed here. The back cover of the casing has 12 screws specifically. So, the 12-bolt rear differential is named after this special feature.

However, the 12-bolt rear differential was first designed in the early 1960s. In turn, many General Motors cars began to have these components from 1964 to 1972. In 1982, the 12-bolt rear differential was introduced in trucks.

Main Objective

Additionally, this set of parts was developed to cope with higher amounts of power. Of course, this is related to the evolution of the trucks through those same years.

So, it is the perfect complement for those trucks with better performance. Identifying the 12-bolt rear differential is also simple.

Identification by Parts

As with the 10-bolt differential, the rear cover of the housing must be checked here. So, it is necessary to remove the cover to check the size of the ring gear. In this case, the diameter should be 8 – 7/8 inches in diameter.

Anyway, finding 12 bolts on the housing cover is a more than obvious sign. Of course, they can be implemented in another way to be able to identify this part. Beyond that, it is the main clue to be found.

Read Also: Best Chevrolet Cam For 4.8 Vortec

ID Code

In many cases, the analysis can be done by the casting number. To do this, the central cast-iron section at the bottom must be checked.

Here, it is possible to know the factory of origin, the casting date, the assembly, the gear ratio, and even the vehicle’s make and model.

Chevy 14 Bolt Rear end Identification

The moment we talk about 14-bolt on a Chevy truck rear end interchange, we can find three different types of 14-bolt axles. So, some are semi-floating versus those that are full floating.

A truck that is used for heavy-duty has a full float. Additionally, the semi-floating is used in trucks that carry a lower workload.

Along with that, the 14-bolt axle has a 10.5-inch ring gear when it is full floating. So, there are different ways to detect the specific design of the 14-bolt rear axle.

Fully Floating

To detect this type of rear axle, you only need to check the wheels. So here we can find everything we need to detect a full floating rear axle.

Particularly, we can notice one end of the axle that protrudes very noticeably when we look at a wheel’s surface.

In particular, this part of the 14 for not fully floating axle protrudes 2 to 4 inches from the wheel. So, it will not be necessary to position under the vehicle.

Semi-floating

As we have considered, fully floating 14-bolt axles are much stronger than semi-floating 14-bolt axles. So, this type of 14-bolt axle has a 9.5-inch-diameter ring gear.

Either way, this is an excellent improvement over a 10-bolt rear axle. In particular, here, you can see how many nuts a 14-bolt semi-floating axle has.

Thus, here the user will find between 8 and 6 nuts. When there are eight nuts but there is no visible shaft end, it is a semi-floating 14-bolt shaft.

11.5″ 14-bolt Shaft

To detect if it is a 14-bolt shaft, it is also possible to check the ring gear diameter. Only girth gears with a diameter of 11.5 inches are part of full-floating 14-bolt shafts.

Hence, an 11.5-inch 14-bolt semi-floating axle is not available.

Chevy Rear End Compatibility

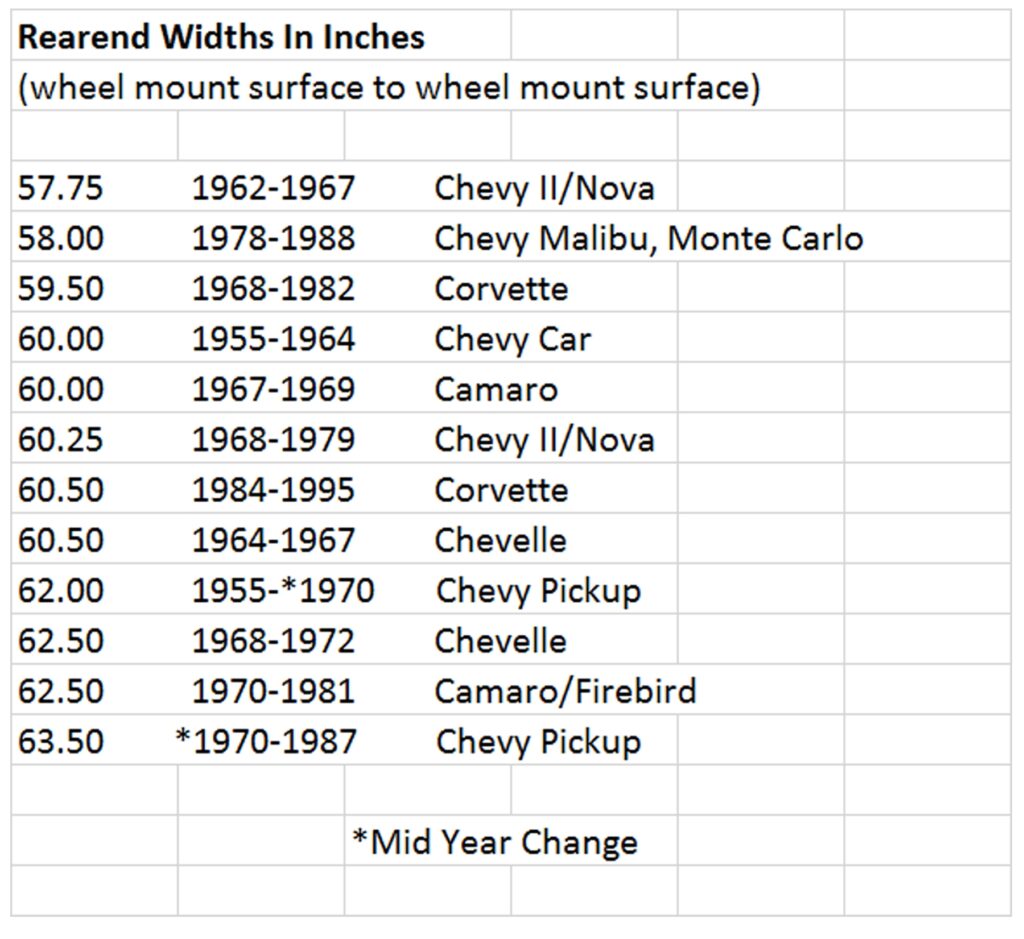

In this case, it is necessary to consider that the different rear parts of a Chevy vehicle may offer specific functionality. So, to be able to use these parts, the compatibility of the different components must be known.

Of course, this is because different components have different designs for different vehicles.

Chevy 10 Bolt Rear End

The moment a ten bolt rear end is included, we are probably talking about some type of automobile. In particular, automobiles that were manufactured between 1971 and 1987 and featured a ten bolt rear end.

In this case, some of the most notable names are Nova, Camaro, and Chevelle. However, in later years, a 12-bolt rear end and a 14-bolt rear end began to be implemented.

Either way, the compatibility of the 10-bolt rear end covers cars up to 450 horsepower. At the same time, there is a wide variety of 10-bolt rear ends with a ring gear of different diameters.

Chevy 12 Bolt Rear End

To complement the production of G-series vans or C-series pickups, a 12-bolt rear end was required. Unlike the 10-bolt rear end, these components were typically included for vans that had to handle higher horsepower.

In turn, 12-bolt rear end compatibility includes some vehicles such as Monte Carlo and Chevelle.

Chevy 14 Bolt Rear End

A 14-bolt axle is often included on many General Motors SUVs, vans, or trucks. This is especially incorporated when it is a ¾ and one-ton vehicle.

In particular, a 14-bolt rear axle can be found on many General Motors 2500 HD trucks. In the same vein, many Suburban trucks also include this design.

Additionally, compatibility also encompasses some trucks built from 2001 onward. So, these diesel trucks began using the 14-bolt rear axle because of its 11.5-inch ring gear.

Of course, this was intended to meet the increased demand for these trucks due to many heavy-duty jobs.

Conclusion

By having an excellent Chevy truck rear end swap, you can get more efficient results. This can be helpful when the same Chevy truck needs to be used in different truck activities.

So, if you are wondering, Chevy truck rear end interchange? Here you can find the answer. Additionally, each rear end has been manufactured specifically to meet the needs of certain vehicles.

Therefore, there is a specific rear end for various types of trucks and various requirements. In turn, it will not be necessary to spend several hours finding out which rear end is specific to your vehicle.

Even this is necessary since Chevy trucks can offer a large range of various utilities. So, this means that not all Chevy trucks are typically used for heavy-duty service.

Those users who have one of these trucks will probably need heavier-duty parts. For that, it is possible to use this guide and have a much stronger and more efficient heavy-duty rear end.

In any case, the replacement of the various parts might involve the work of a qualified technician. As we have noted, this is a set of essential parts for the operation of a vehicle.

Hence, it is required to apply for a good job.